Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

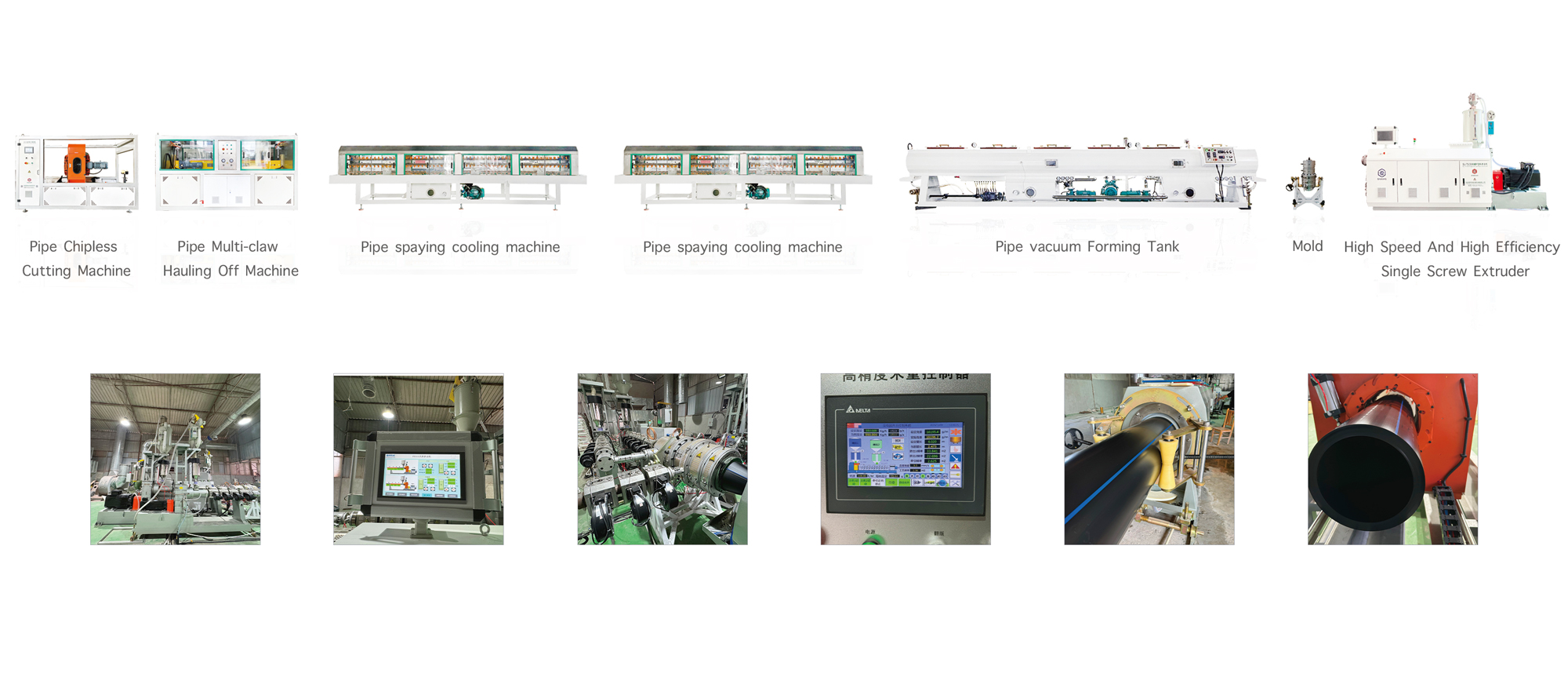

High-efficiency HDPE pipe extrusion line with vacuum sizing, multi-layer co-extrusion, online diameter control, and PLC automation for stable mass production.

Product Overview

The HDPE Pipe Extrusion Line is a state-of-the-art system designed for the continuous production of strong, lightweight, and corrosion-resistant HDPE and PE pipes. Built for high performance, it combines precision extrusion technology, advanced control systems, and efficient cooling methods to deliver pipes that meet strict international standards.

This PE Pipe Production Line is ideal for manufacturing pipes for municipal water systems, gas transportation, agricultural irrigation, and industrial fluid handling. Its modular design allows easy customization for different pipe diameters, wall thicknesses, and output capacities.

| Model | Diameter Range | Extruder Model | Max Output | Power Consumption |

|---|---|---|---|---|

| HDPE-110 | 20–110 mm | SJ-65/33 | 180 kg/h | 65 kW |

| HDPE-250 | 75–250 mm | SJ-75/33 | 320 kg/h | 110 kW |

| HDPE-450 | 160–450 mm | SJ-90/33 | 550 kg/h | 165 kW |

| HDPE-800 | 315–800 mm | SJ-120/33 | 900 kg/h | 280 kW |

| HDPE-1200 | 630–1200 mm | SJ-150/33 | 1300 kg/h | 400 kW |

![]()

Share your target OD range, wall/SDR, throughput or line speed, standards (ISO/EN/ASTM, CE/UL), and delivery timeline. We’ll return a tailored configuration, layout, lead time, and quotation.