Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

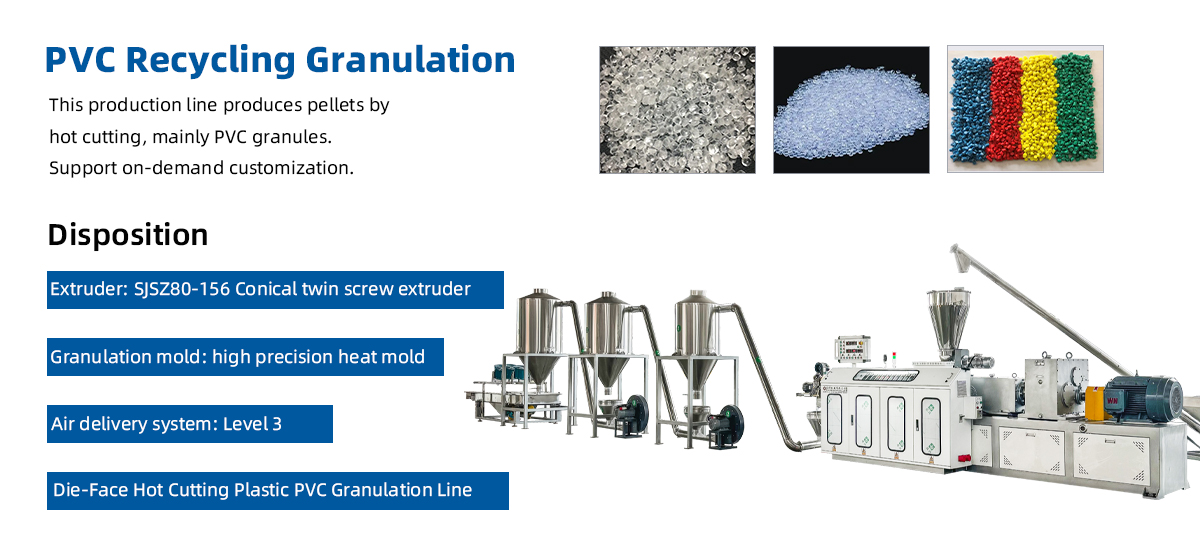

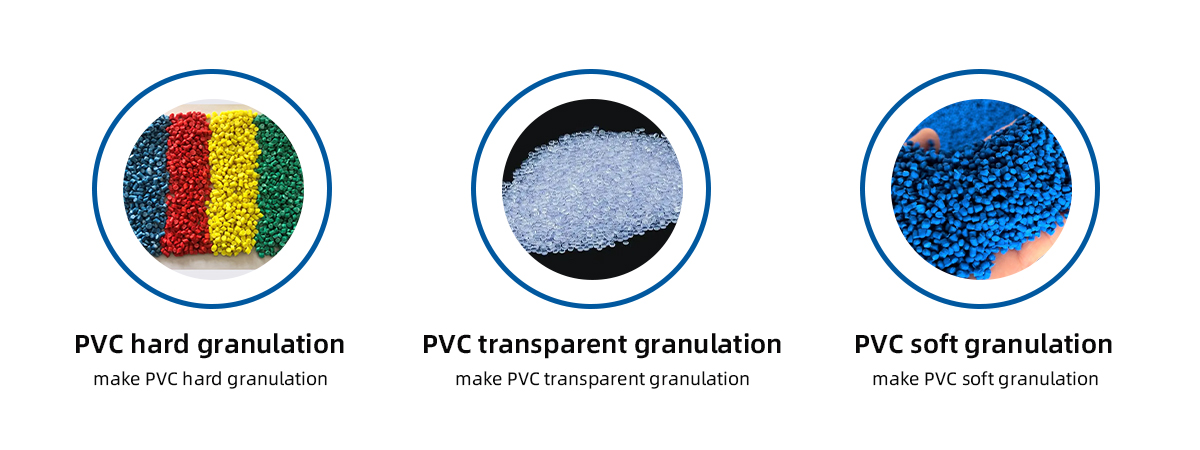

High-performance PVC Pelletizing Production Line for producing uniform PVC granules from virgin or recycled materials. Suitable for pipes, profiles, films, cables, and more. Energy-efficient, durable, and customizable to your production needs.

The PVC Pelletizing Production Line is specially engineered to transform PVC powder, scraps, or recycled materials into high-quality pellets (granules) for further processing. With advanced extrusion, cutting, and cooling technologies, this line guarantees stable performance, uniform pellet size, and efficient operation. It is widely used in PVC pipe, profile, film, and cable manufacturing industries, making it a versatile choice for both new material and recycling applications.

Extruder Type:

Single Screw Extruder: Suitable for simple PVC pelletizing with stable operation.

Twin Screw Extruder: Best for compounding PVC with additives, stabilizers, fillers, or recycled materials.

Screw Diameter: 51 mm – 135 mm (customizable according to output requirement)

L/D Ratio (Length to Diameter): 22:1 – 36:1 (optimized for mixing and plasticizing efficiency)

Main Motor Power: 37 kW – 110 kW (energy-saving AC or servo motor options available)

Output Capacity:

Single Screw: 100 – 500 kg/h

Twin Screw: 200 – 1000 kg/h

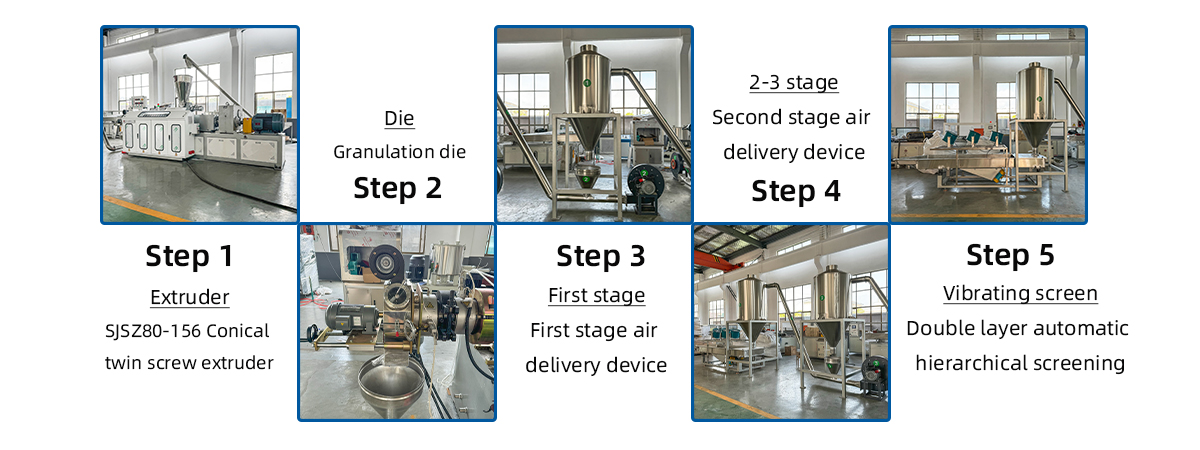

Pelletizing Methods:

Strand Cutting: Pellets are cooled in water bath and cut into granules, flexible and easy maintenance.

Die-Face Cutting: Pellets cut directly at die face, suitable for high-capacity production.

Water Ring Pelletizing: Ensures uniform size, good for soft PVC and recycled PVC.

Cooling System:

Air cooling system (for standard granules)

Water cooling & water ring system (for high-speed pelletizing and heat-sensitive PVC)

Control System: Siemens PLC with touchscreen + automatic temperature control (PID control with ±1°C precision).

Pellet Size: 2 – 5 mm (adjustable by cutter speed and die design)

Voltage Supply: 380V / 50Hz, 3 Phase (customizable for different countries)

Auxiliary Equipment:

Force feeder or side feeder (for light or recycled materials)

Cooling water tank (stainless steel, 3–6 meters length)

Strong pellet cutter with adjustable speed

Vibrating screen for separating qualified pellets

Storage silo with air conveying system

PVC pellets produced by this extrusion and pelletizing line are widely applied in:

Q1: What is the purpose of PVC pelletizing?

PVC pelletizing converts PVC resin or recycled PVC into uniform pellets, making them easier to process in downstream applications.

Q2: Which cutting method should I choose?

Q3: Can the machine handle recycled PVC?

Yes, the line is designed to process both virgin and recycled PVC materials.

Looking for a reliable PVC Pelletizing Production Line? Get in touch with us today for technical details, machine videos, and customized quotation.