Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

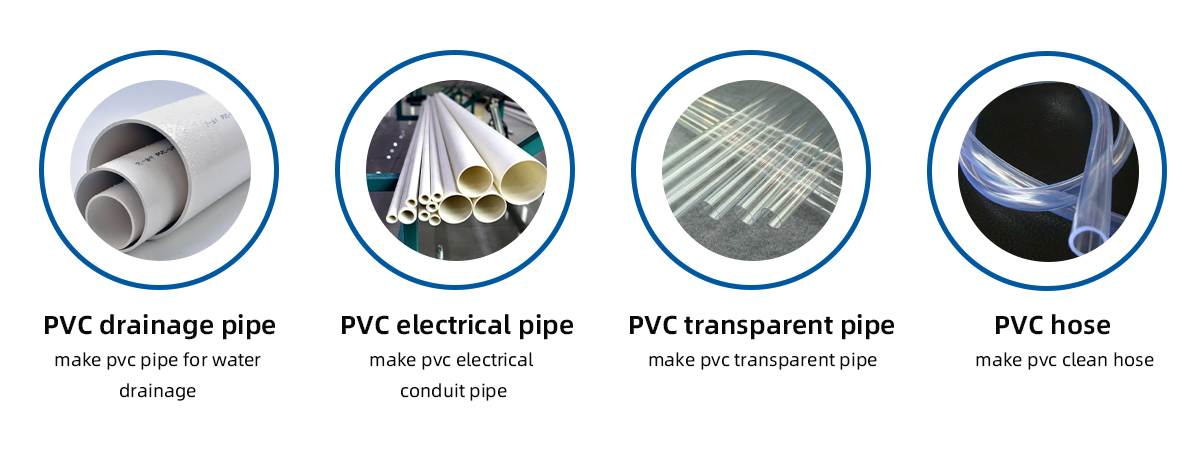

Compact PVC Pipe Extrusion Line 16-63mm with vacuum sizing, inline OD control, PLC/HMI, planetary/chipless cutting, and socketing options for water & conduit.

Short description

High-stability PVC pipe extrusion line for 16–63 mm UPVC/CPVC pipes used in water supply, electrical conduit, and plumbing. Turnkey delivery with installation, training, and after-sales service.

| Item | Typical Value | Notes |

|---|---|---|

| Pipe OD Range | Ø 16–63 mm | SDR/SCH per standard |

| Wall Range | 2.0–5.8 mm | Depends on class/SCH |

| Throughput | 120–280 kg/h | Extruder & formulation dependent |

| Line Speed | 6–22 m/min | Size, wall, cooling dependent |

| Materials | uPVC / CPVC | Lead-free stabilizers supported |

| Control | PLC + 7″/10″ HMI | Recipes, alarms, data export |

| Gauging (opt.) | Laser OD / ultrasonic wall | Closed-loop OD control |

| Socketing | R/RR/S | Inline or offline |

Actual performance varies with resin (CaCO₃ level/stabilizer), tooling, cooling capacity, and target standard.

Mixing → Feeding → Twin-Screw Extrusion → Die Head → Vacuum Calibration → Spray Cooling → Haul-Off → Cutting → Belling → Stacking & Inspection

Extruder: conical twin-screw (SJZ51/105, SJZ65/132), multi-zone heating

Die Head: spiral distributor die; multi-cavity options for small sizes

Vacuum Sizing Tank: stable vacuum, level & temperature control

Cooling Section: multi-stage spray/cascade with filtration & UV

Haul-Off: caterpillar/belt type, closed-loop synchronization

Cutting: planetary or chipless; optional chamfer & dust control

Socketing (opt.): inline belling machine with internal cooling mandrel

Metrology (opt.): in-line laser OD, ultrasonic wall, SPC dashboards

Q1: What’s included in a standard 16–63 mm line?

A: Extruder, die & calibration sleeves, vacuum tank, spray cooling tank, haul-off, cutter, inline belling (optional), stacker, and PLC-HMI controls.

Q2: How do I choose capacity and extruder size?

A: We match extruder model and tooling to your target diameters, wall thickness, resin formula, and desired throughput. Share your specs and we’ll size the line accordingly.

Q3: Inline vs. offline belling—how to choose?

A: Inline belling improves efficiency and reduces handling; offline suits small batches or special socket requirements. Both are supported.

Q4: How to minimize ovality and keep diameter within tolerance?

A: Stabilize melt temperature, use the right calibration sleeves, ensure uniform spray cooling and traction, and add inline diameter measurement for closed-loop control.

Q5: What services are included after delivery?

A: Installation & commissioning, operator training, spare parts, and remote diagnostics for quicker troubleshooting.

Ready to configure your PVC Pipe Extrusion Line 16–63 mm?

Contact us with your target sizes, application, expected output, and local utilities for a tailored layout, BOM, and quotation.