PE Small Pipe Extrusion Line — High-Speed LDPE/LLDPE/HDPE Tube Manufacturing

What It Is

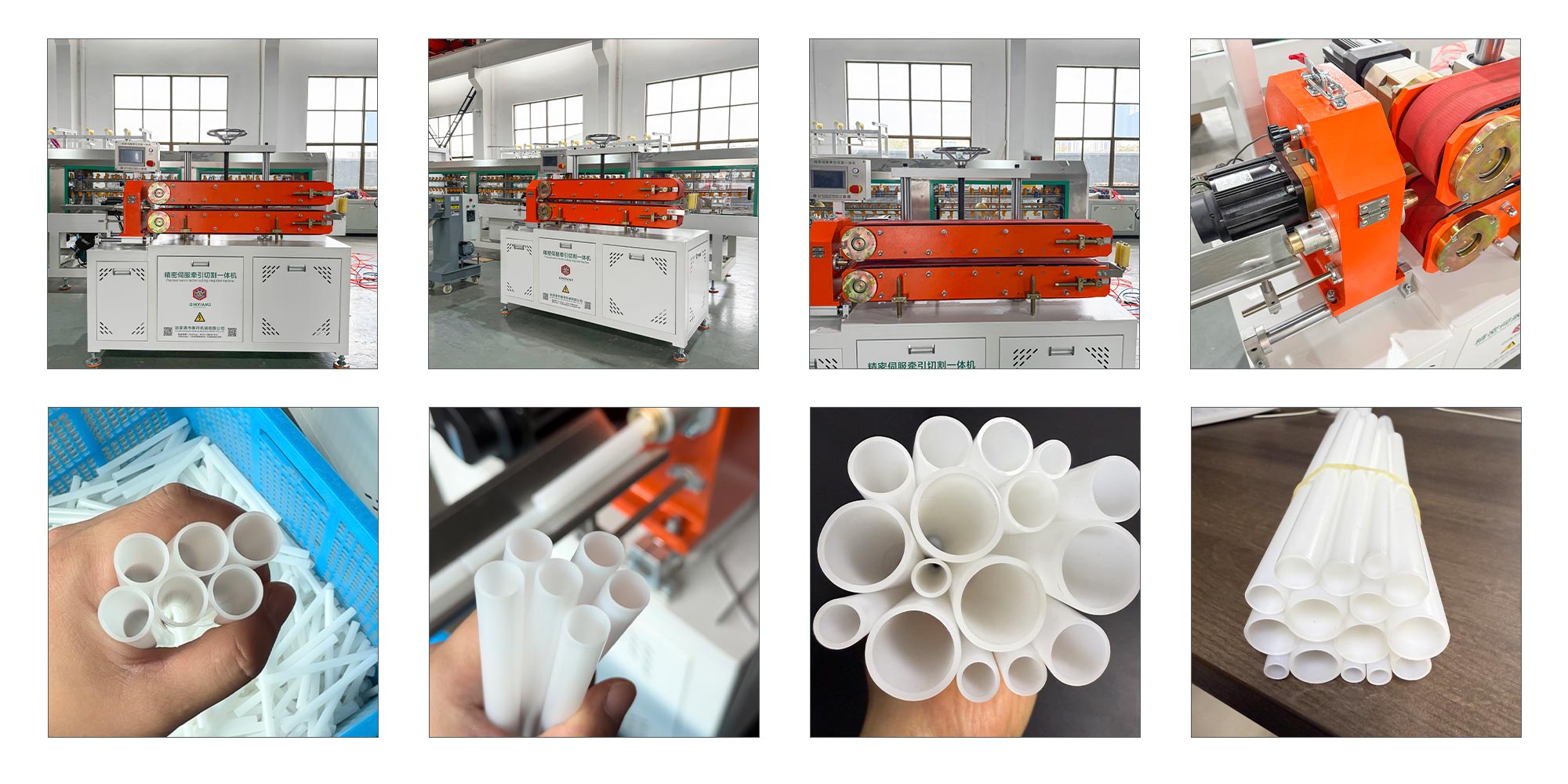

Our PE Small Pipe Extrusion Line is a turnkey solution for producing micro to small-diameter polyethylene tubes (LDPE/LLDPE/HDPE). It combines optimized screw design, precise temperature zones, PLC + touchscreen HMI, and closed-loop line synchronization to deliver uniform wall thickness, smooth surface finish, and stable 24/7 output.

Key Features & Benefits

- High speed & stability – Optimized screw/barrel and melt filtration enable continuous, stable extrusion with consistent OD/ID.

- Precision sizing – Vacuum calibration and multi-stage spray cooling keep ovality low; online diameter/Wall-thickness measurement available.

- Energy efficiency – Insulated heating zones and VFD drives reduce kWh per kg; closed-loop water system optional.

- Smart operation – PLC + HMI for recipe management, line-wide synchronization, alarms, and production data export.

- Fast changeovers – Quick-change die heads and adjustable sizing sleeves minimize downtime for multi-spec production.

- Compliance & safety – CE/UL-ready electricals, interlocks, and EMC design.

Typical Applications

- Wire & cable conduit / lead tubes – Low-friction bore, abrasion resistance.

- Micro-irrigation lateral / dripper line – Flexible, durable small OD tubing.

- Home renovation micro tubing – Water, air, or signal routing.

- Medical & lab tubing (material and regulatory review required).

- Packaging straws / protective tubes / bubble-film skeleton microtubes.

Process Flow

Feeding & drying (as needed) → Extrusion & melt filtration → Die head & vacuum sizing → Multi-stage water cooling → Haul-off (closed loop) → Metering & coding → Cutting/Coiling → In-line QC & packaging

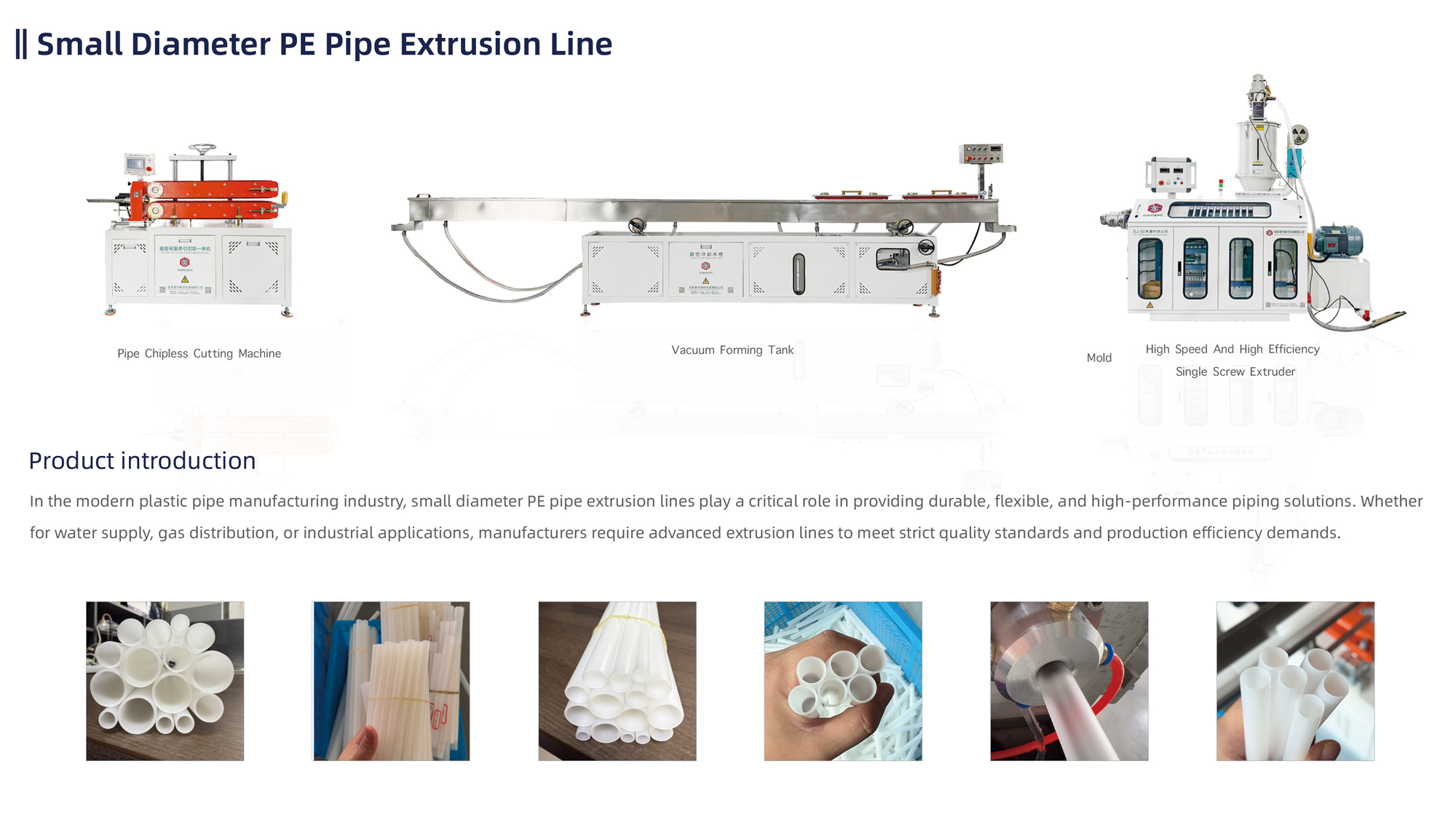

Core Modules

- High-efficiency single-screw extruder (nitrided barrel, wear-resistant screw, optimized L/D)

- Precision die head with quick-change tooling

- Vacuum calibration tank (stable vacuum, level & temp control)

- Spray cooling tanks (closed-loop option)

- Servo or caterpillar haul-off, synchronized with main extruder

- Fly-knife or planetary cutter / servo coiler (small pipe commonly uses coiler)

- Meter counter, inkjet/laser coder (optional)

- Online diameter & wall-thickness gauge with SPC (optional)

Technical Specifications (customizable)

- Pipe OD range: Ø 2–32 mm (options down to Ø 1.5 mm or up to Ø 40 mm)

- Line speed: up to 60 m/min depending on OD, material, and cooling capacity

- Throughput: approx. 80–180 kg/h*

- Energy consumption: 0.28–0.45 kWh/kg*

- Control system: PLC + 7”/10” HMI; recipe/alarms/data export

- Utilities: Electrical per region, process water; closed-loop chiller recommended

- Standards: CE/UL (optional)

*Actual data depends on your target size, formulation, and configuration.

Quality & Cost Control

- Wall-thickness uniformity: Balanced melt flow + stable vacuum reduce eccentricity.

- Surface finish: Tuned cooling profile mitigates orange-peel and water marks.

- Lower cost per meter: Energy-saving design, low scrap rate, and easy maintenance cut operating costs.

Customer Case

Delivery & Service

- On-site installation and ramp-up support

- Operator & maintenance training with manuals and spare-parts list

- Remote diagnostics via PLC; fast after-sales response

Call to Action

Tell us your OD range, target line speed or throughput, material (LDPE/LLDPE/HDPE), and certification needs (CE/UL). We’ll send a customized configuration and quotation.