Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

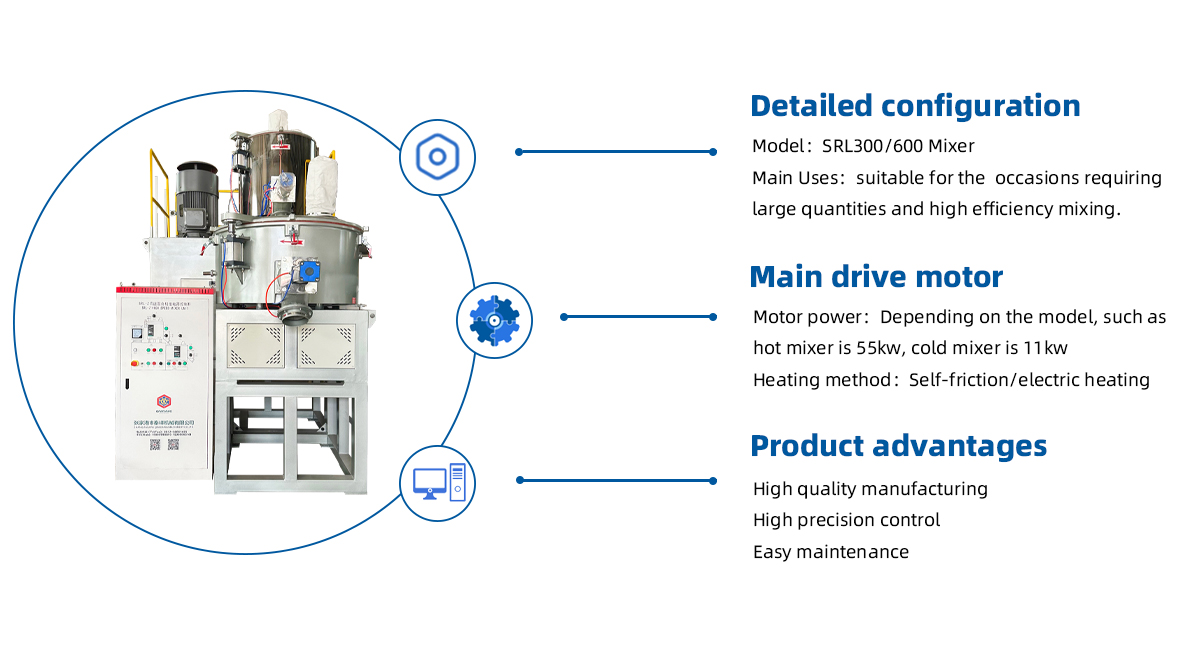

The SRL300-600 high-speed mixer is an industrial-grade, twin-stage mixing solution engineered for medium to large batch compounding of PVC, PP, and PE. With high-shear dispersion, rapid thermal exchange, and robust process control, it delivers consistent dry blends and masterbatch quality for building materials, furniture, cable, and automotive applications.