Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

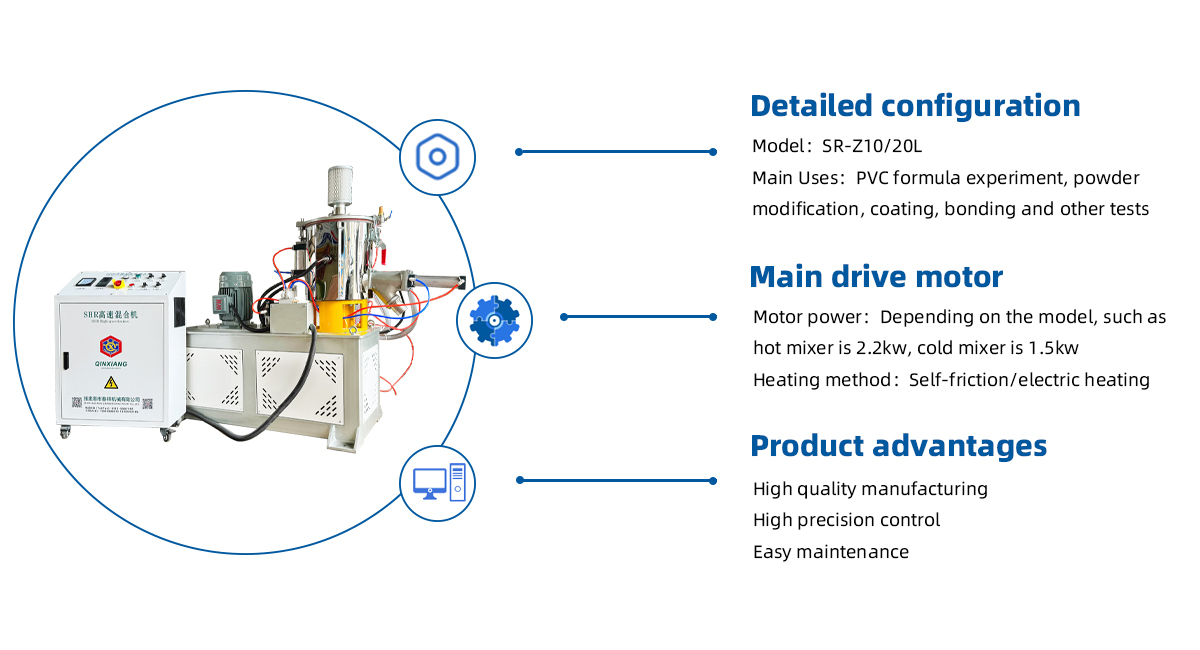

The SRL10L laboratory high-speed mixer is a compact, high-shear mixing solution engineered for R&D, QC labs, and pilot-scale production. It delivers fast heat exchange, uniform dispersion, and repeatable batch quality for PVC dry blend, PP/PE compounds, and color masterbatch, helping you scale innovations from lab to production.