PVC Profile Extrusion Line – High Output, Smart Control, and Premium Surface Finish

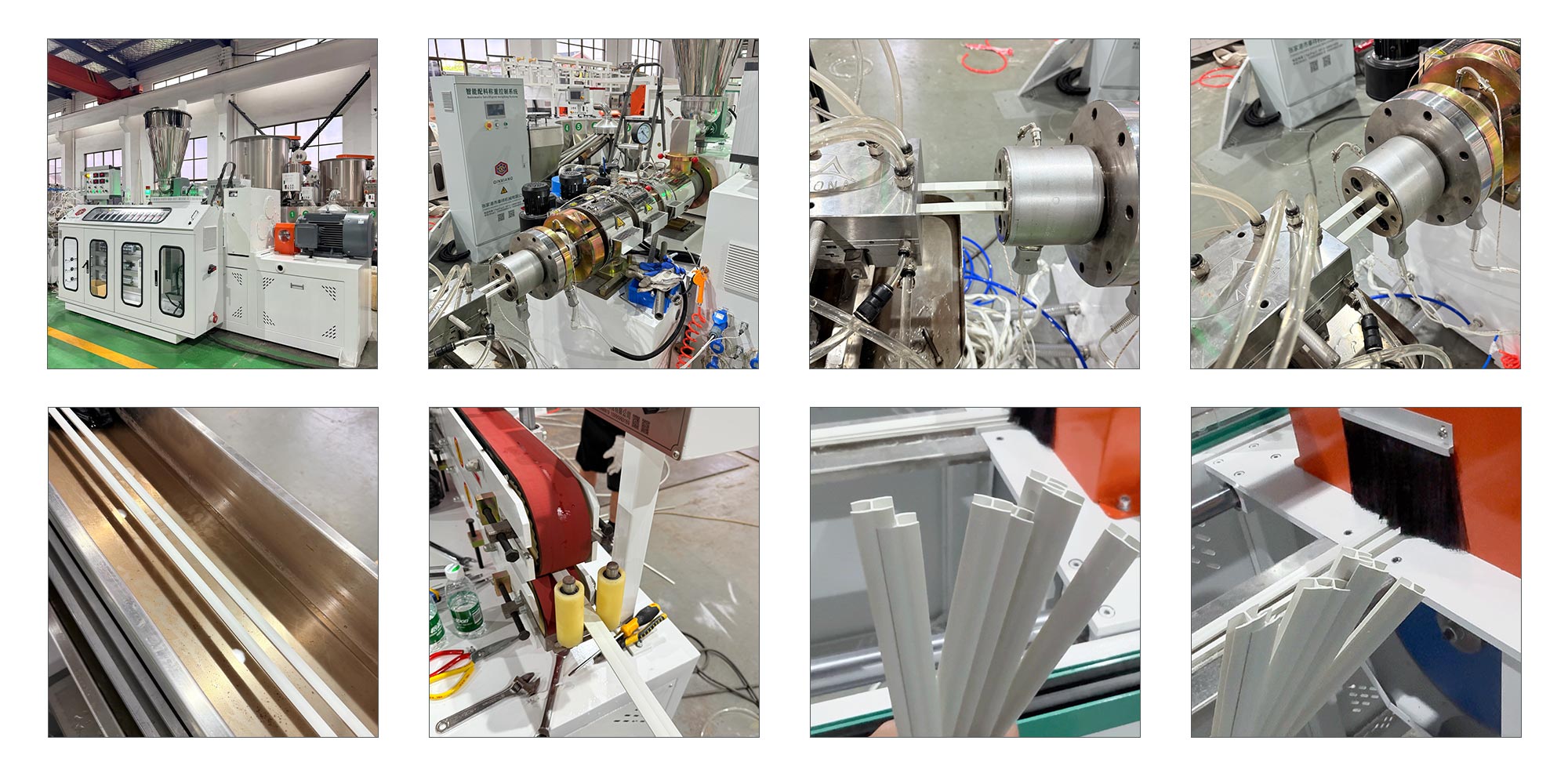

A high‑efficiency PVC profile extrusion line engineered for stable output, glossy surfaces, tight tolerances, and rapid changeovers—ideal for window profiles, decorative trims, cable ducts, and customized shapes. Built around the SJZ55‑110 conical twin‑screw extruder, a 4.5 m stainless‑steel vacuum calibration and cooling tank, a belt haul‑off machine, and a lift‑up cutting saw, this turnkey solution delivers lower total cost of ownership and superior market competitiveness.

Product Features

Unique Advantages, Material Characteristics, and Process Know‑How

- Wide processing window for rigid and semi‑rigid PVC, supports recycled PVC (up to 30%+) and co‑extrusion cap layers/seals for enhanced UV and scratch resistance.

- Compatible with Ca‑Zn stabilizers, RoHS/REACH‑compliant formulations, and low‑smoke halogen‑free options; optimized screw geometry ensures thorough plastication and low shear.

- Precision melt management and low‑pulsation metering minimize flow marks, improve gloss, and stabilize dimensions on complex PVC profiles.

- Modular tooling with quick‑change die rails shortens setup time; PID‑controlled multi‑zone heating (±0.5°C) ensures repeatable quality across SKUs.

- Energy‑saving drives, VFD‑controlled pumps/blowers, and insulated barrel zones reduce specific energy consumption while maintaining output.

Core Equipment Highlights

- SJZ55‑110 Conical Twin‑Screw Extruder: high torque, strong feeding, bimetallic barrel and wear‑resistant screws for longevity in filled/recycled formulations.

- 4.5 m Stainless‑Steel Vacuum Calibration Tank: multi‑zone vacuum, dual‑mode cooling (water curtain + fine mist) for sharp edges, straightness, and minimal warpage.

- Belt Haul‑Off Machine: closed‑loop speed control and soft belt surfaces protect delicate profiles and ensure constant line speed.

- Lift‑Up Cutting Saw: burr‑free cutting, accurate length control; supports inline length metering and inkjet coding for end‑to‑end traceability.

Application Areas

Building and Construction

- PVC window and door profiles, wall and ceiling panels, skirting boards, siding, corner guards, expansion joints, cable trays.

Furniture and Interior

- Decorative moldings, cabinet trims, wardrobe frames, LED channels and covers, edge profiles, protective strips.

Automotive and Transportation

- Interior trims, seal profiles, cable conduits, RV/trailer furniture profiles, window guides, protective channels.

Electrical and Industrial

- Wire management ducts, instrument covers, display frames, machine guards, logistics rack profiles, custom OEM/ODM parts.

Technical Specifications

Equipment Configuration

- Extruder: SJZ55‑110 conical twin‑screw extruder; bimetallic barrel; wear/corrosion‑resistant screws; low‑pulsation metering.

- Calibration and Cooling: 4.5 m stainless‑steel vacuum calibration and cooling tank; multi‑zone vacuum; water curtain + mist cooling; stainless fittings and gauges.

- Downstream: belt haul‑off (closed‑loop speed control), lift‑up cutting saw (tilt/lift design), optional tilt table/stacker; inline length metering and inkjet coding ready.

- Control System: PLC + HMI with recipe library, alarm analytics, multi‑zone PID temperature control; optional inline width/thickness measurement and closed‑loop feedback.

Performance and Capacity

- Output Capacity: 120–220 kg/h for rigid PVC profiles (geometry dependent).

- Co‑Extrusion (optional): 10–40 kg/h per auxiliary extruder for cap layers or soft seals.

- Dimensional Tolerance: typical ±0.2–0.5 mm; high‑gloss surface achievable with optimized die and cooling.

- Changeover Time: 30–60 minutes between similar profiles with quick‑change tooling.

Utilities and Energy

- Power Supply: 380–480 V, 50/60 Hz, 3‑phase (configurable).

- Installed Power: approx. 120–180 kW per line (model/options dependent).

- Specific Energy Consumption: 0.30–0.42 kWh/kg under steady‑state production.

- Cooling Water: 2–5 m³/h at 15–25°C; closed‑loop recommended.

- Compressed Air: 0.6–0.8 MPa for actuators and cutting; noise level <80 dB at 1 m with standard guarding.

User Recognition

Market Performance and Customer Satisfaction

- Deployed across building, furniture, and electrical sectors with consistent uptime and repeatable quality; OEE improvements of 8–15% commonly reported.

- Scrap Reduction: 20–30% after adopting inline measurement and closed‑loop haul‑off control on PVC profiles and ducts.

- Recycled PVC Ready: stable extrusion window with 20–30% recycled content without compromising gloss or tolerance.

Customer Feedback and Case Highlights

- “The SJZ55‑110 provides a forgiving process window—less recipe tweaking, more production time.”

- Case 1: Window profiles—output increased from 160 to 200 kg/h; tolerance held at ±0.3 mm; energy use per kg reduced by ~12%.

- Case 2: Electrical ducts—25% scrap reduction after inline width measurement and haul‑off speed feedback control.

- Case 3: Furniture trims—changeover time cut from 85 to 50 minutes across multi‑SKU schedules.

Customer Case

Why This Line Wins

- Innovative conical twin‑screw core, advanced vacuum calibration, and intelligent control deliver premium surface quality and tight dimensions.

- Faster changeovers, lower energy per kg, and robust wear components reduce total cost of ownership and accelerate ROI.

- Turnkey, CE‑ready solution with OEM/ODM customization to match your profiles, tooling, and plant utilities.