Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

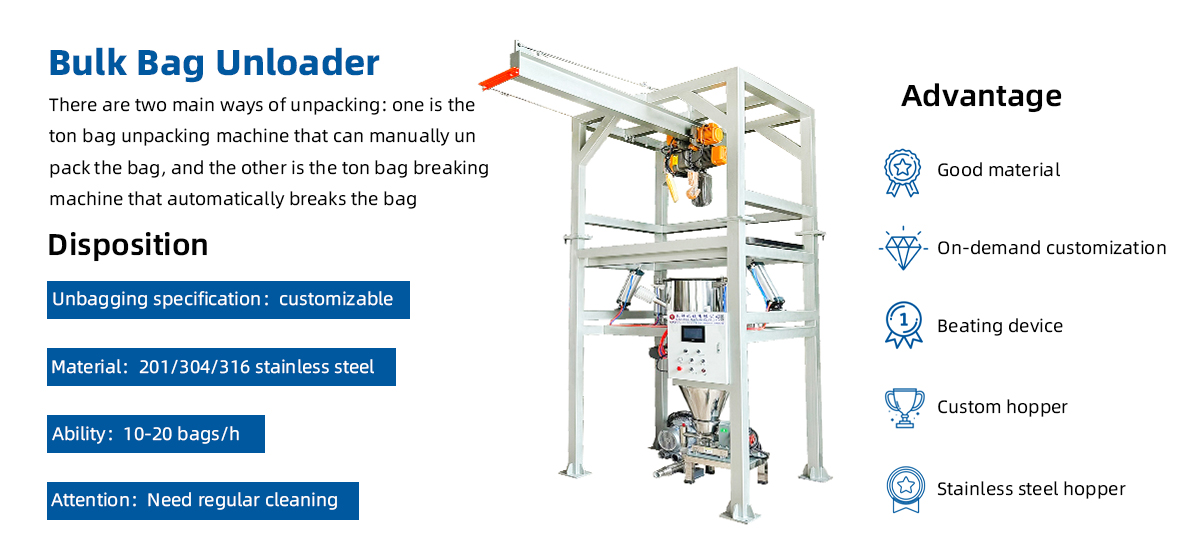

The bulk bag unloader with loss-in-weight feeder is an integrated big bag discharging and gravimetric dosing system designed for continuous, dust-free, and highly accurate feeding of powders and granules. Combining automated FIBC unloading, agglomerate conditioning, and closed-loop weight control, it delivers stable throughput, clean operation, and traceable quality for building materials, plastics, chemicals, food additives, and battery materials.