Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

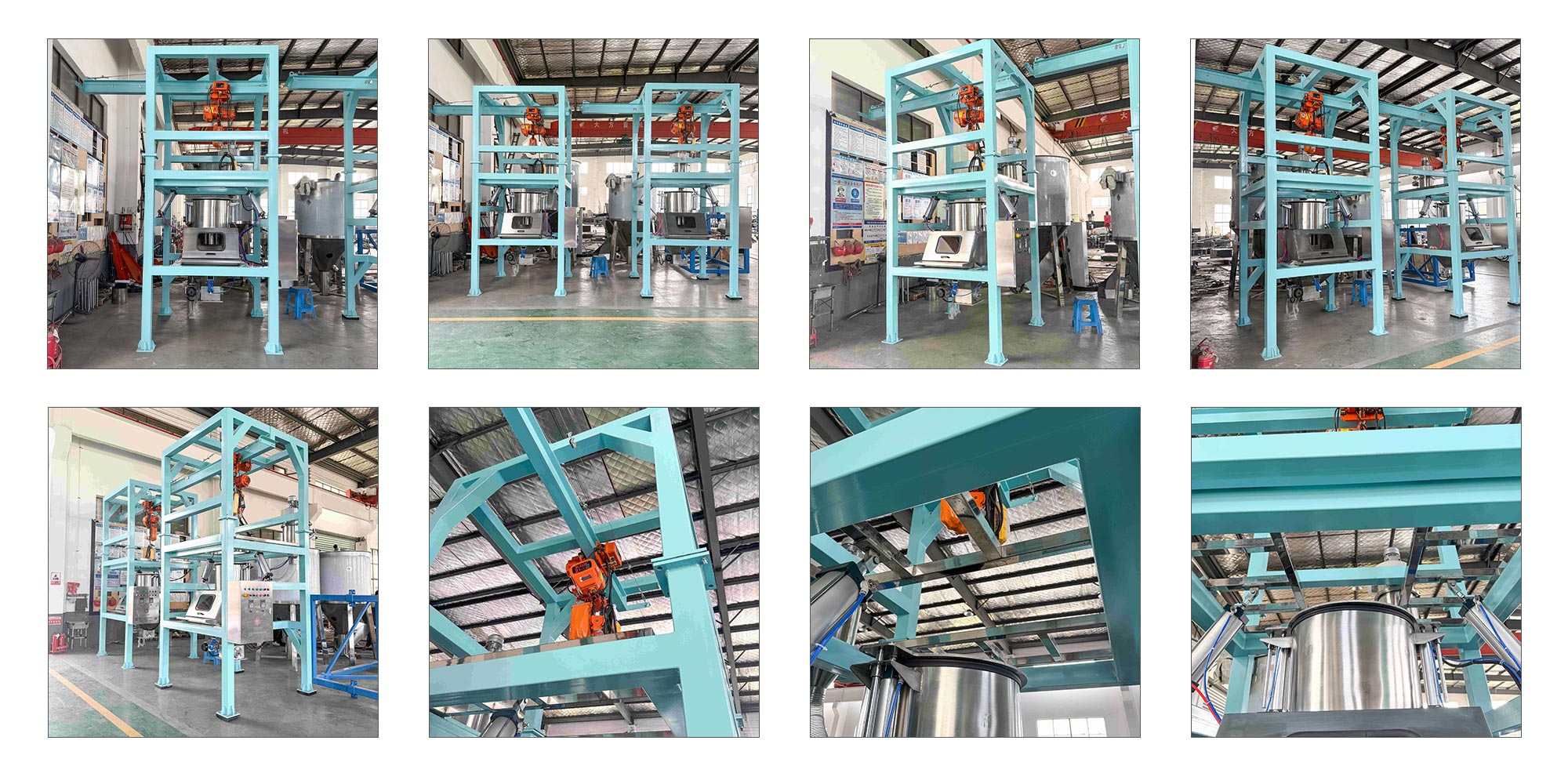

An advanced bulk bag unloader engineered for clean, safe, and efficient FIBC discharge. Featuring dust-tight docking, robust lifting frames, and configurable flow aids, it delivers reliable powder and granule handling across multiple industries with minimal downtime.