Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

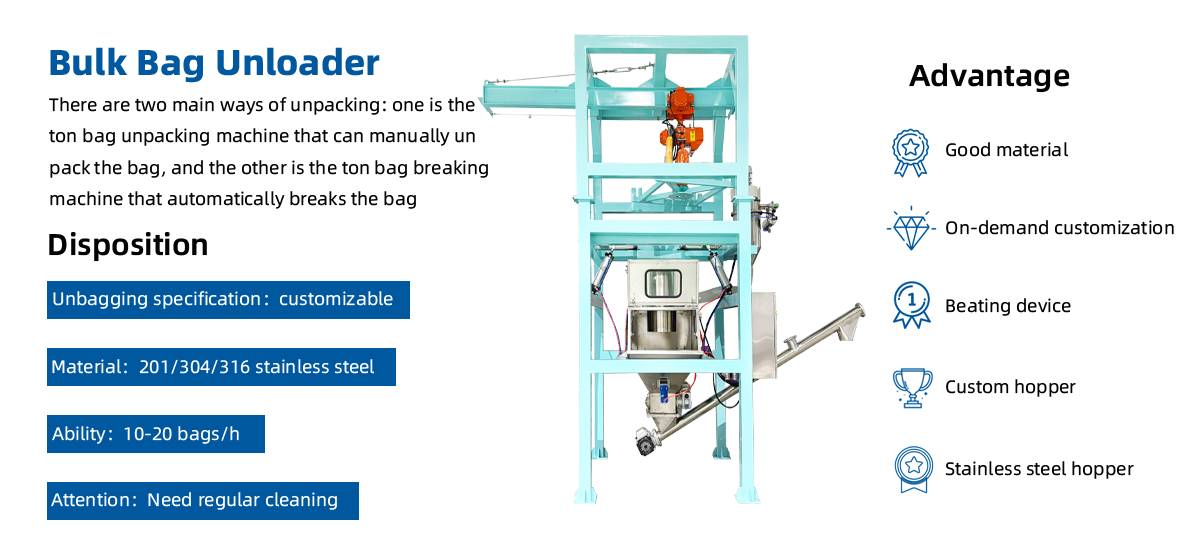

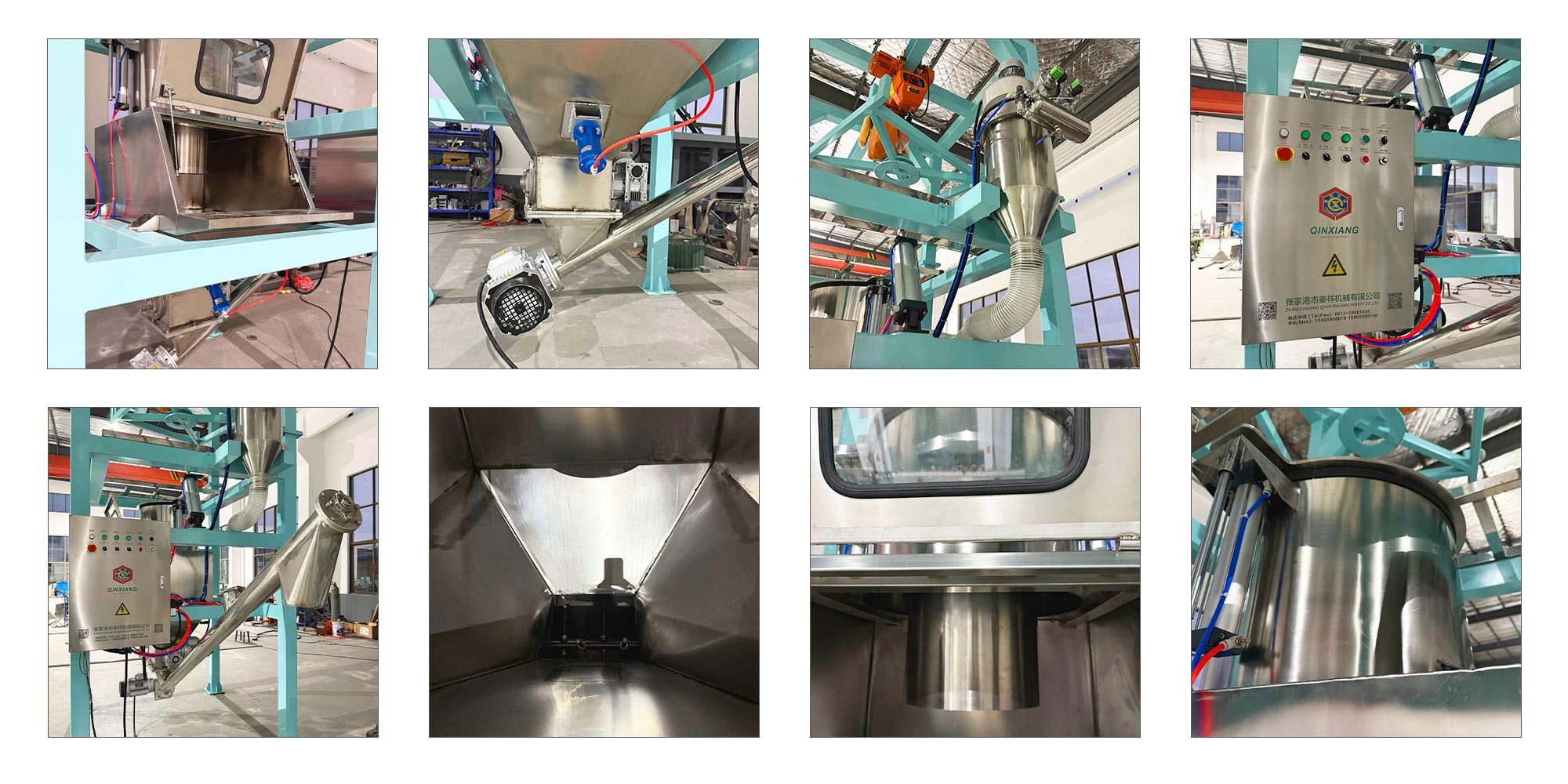

An integrated big bag discharger with a stainless-steel screw conveyor feeder engineered for reliable, dust-tight unloading and continuous conveying of powders and granules. Optimized for stable throughput, low maintenance, and safe operation across construction chemicals, plastics compounding, food ingredients, and battery materials.