Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Introduction

High-Density Polyethylene (HDPE) pipes are widely recognized for their durability, corrosion resistance, and cost-effectiveness. They are used in water supply, gas distribution, irrigation systems, and industrial piping. Modern HDPE Pipe Extrusion Lines make it possible to produce these pipes with high precision, consistent quality, and minimal waste. In this article, we’ll walk through the HDPE pipe manufacturing process step by step.

The process begins with high-quality HDPE granules or PE raw materials. Additives such as UV stabilizers, color masterbatches, and antioxidants may be mixed to enhance performance.

HDPE Pipe Manufacturing Equipment often includes an automatic feeding and dosing system to ensure consistent material ratios.

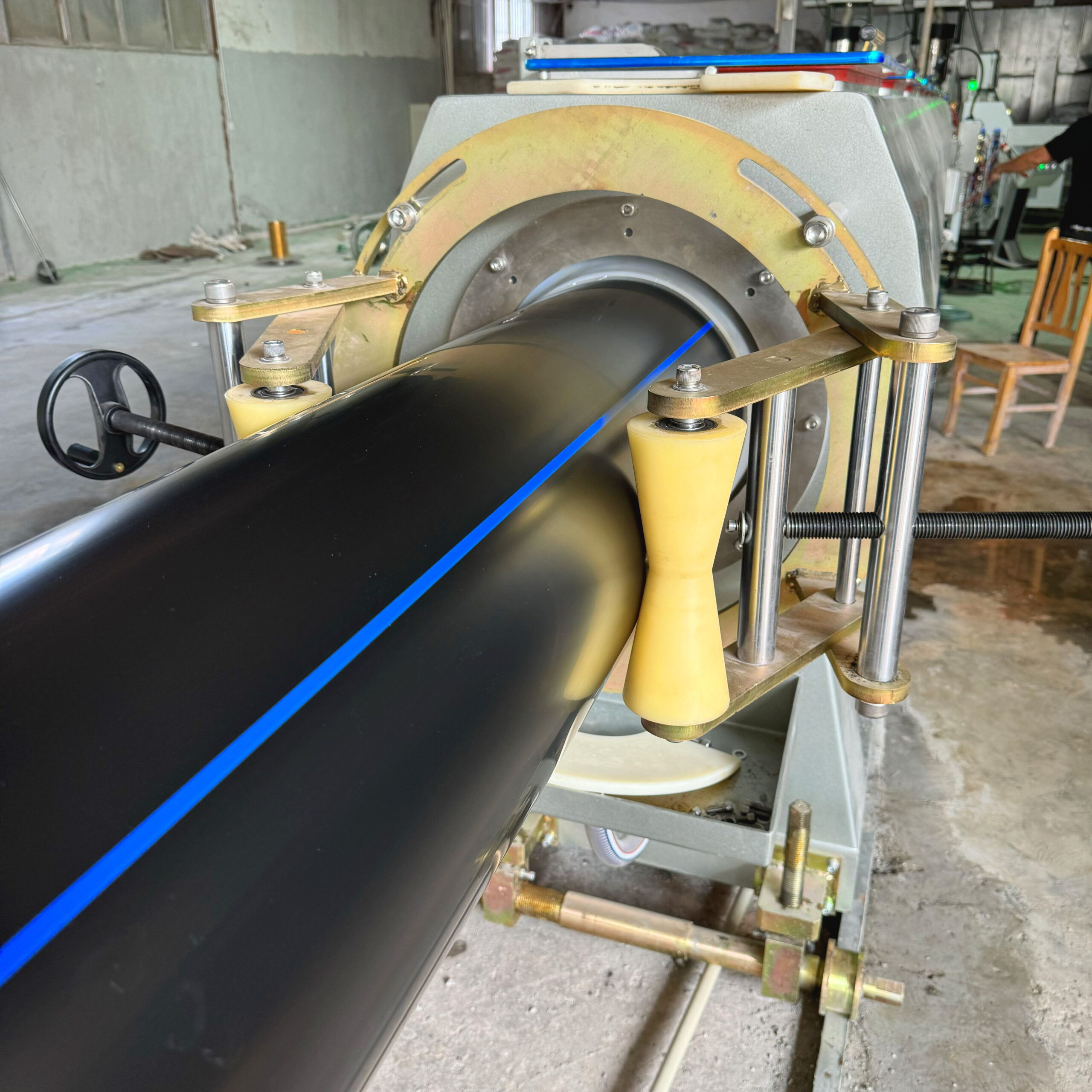

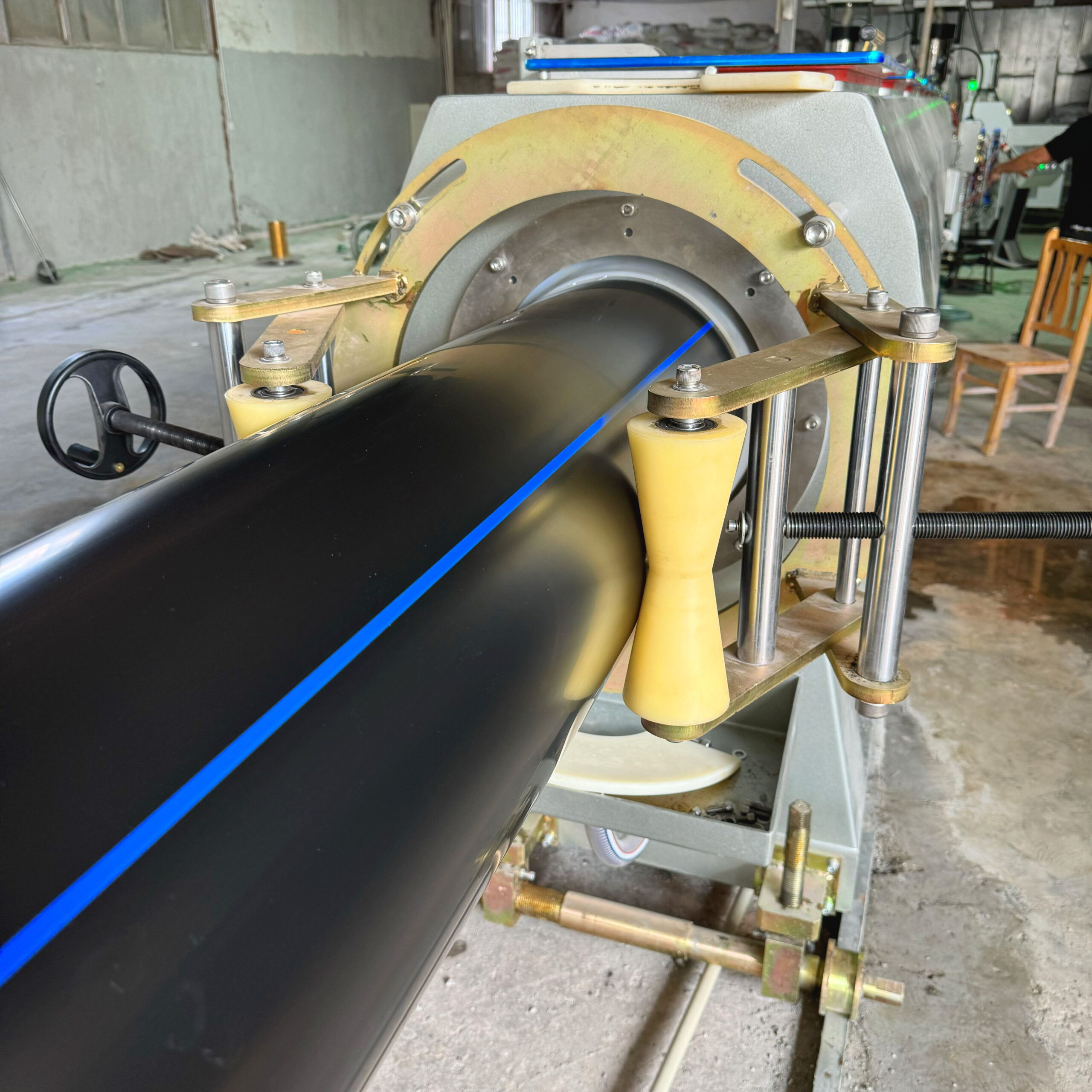

At the heart of the PE Pipe Production Line is the single screw extruder.

The molten HDPE passes through a spiral die head designed for even melt distribution.

The extruded pipe enters a vacuum calibration tank where:

The haul-off unit synchronizes with the extrusion speed to maintain consistent pipe dimensions.

Finally, the pipes are automatically discharged and stacked for packaging. Automated systems reduce manual handling, improve efficiency, and protect the finished product from damage.

The HDPE Pipe Manufacturing Process relies on precision engineering and advanced machinery to produce pipes that meet demanding performance standards. Investing in a high-quality HDPE Pipe Extrusion Line ensures long-term production stability, consistent quality, and a competitive edge in the global pipe market.